Exactech, a company developing joint implants, has given our team the task of redesigning their stemless shoulder implant for reverse use. They wanted us to first improve their design’s resistance between the implant surface and nearby bone. Once we achieved this, they wanted us to adjust the design to make surgical revisions for the implant easier.

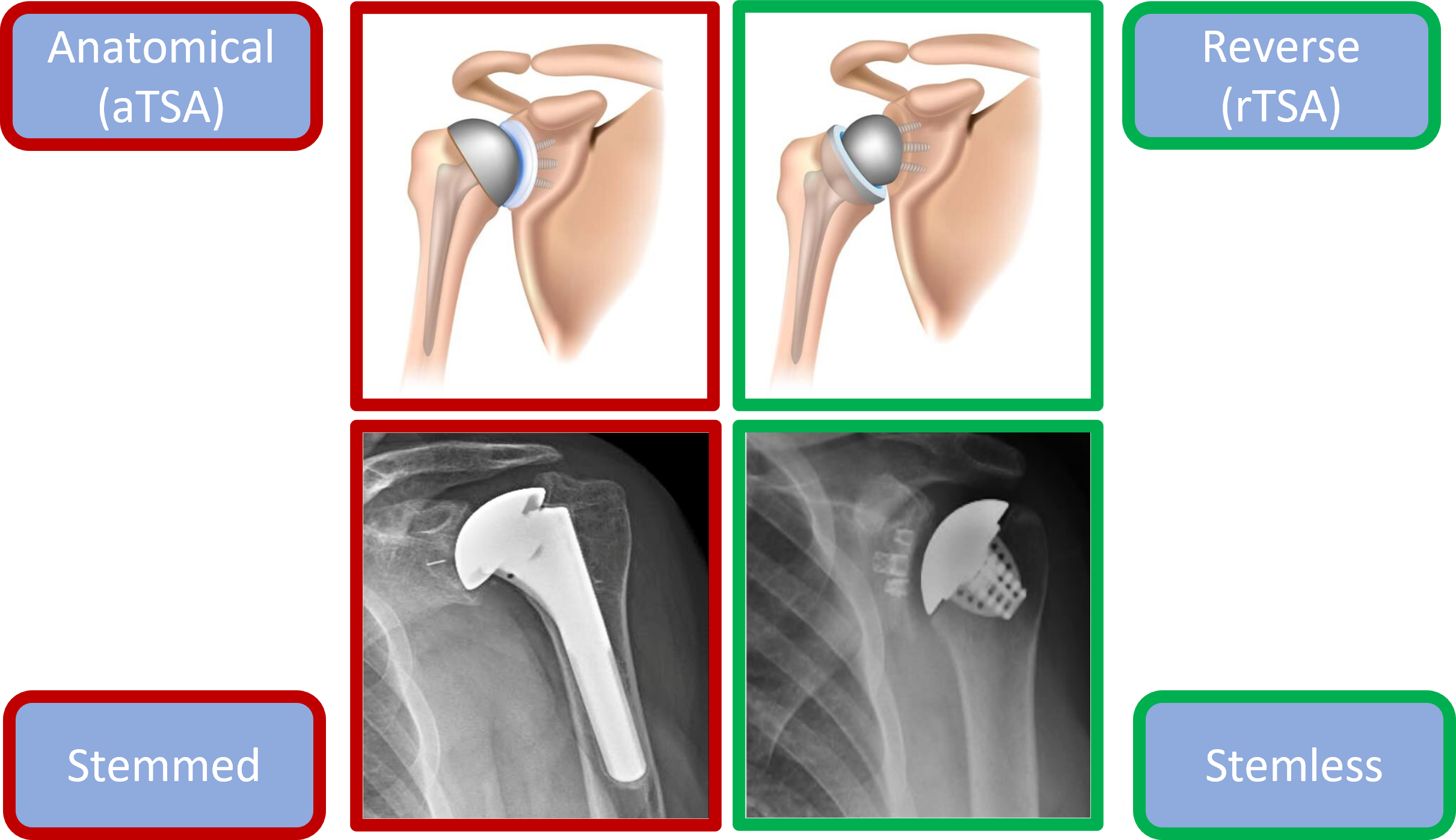

A decrease in joint function can eventually lead to shoulder replacement surgery. Luckily, the field of implants is changing quickly in the modern age. With constant improvement in this field, patients can receive reliable artificial joints that replace the role of their natural joints. Two implant variations are available; stemless and stemmed.

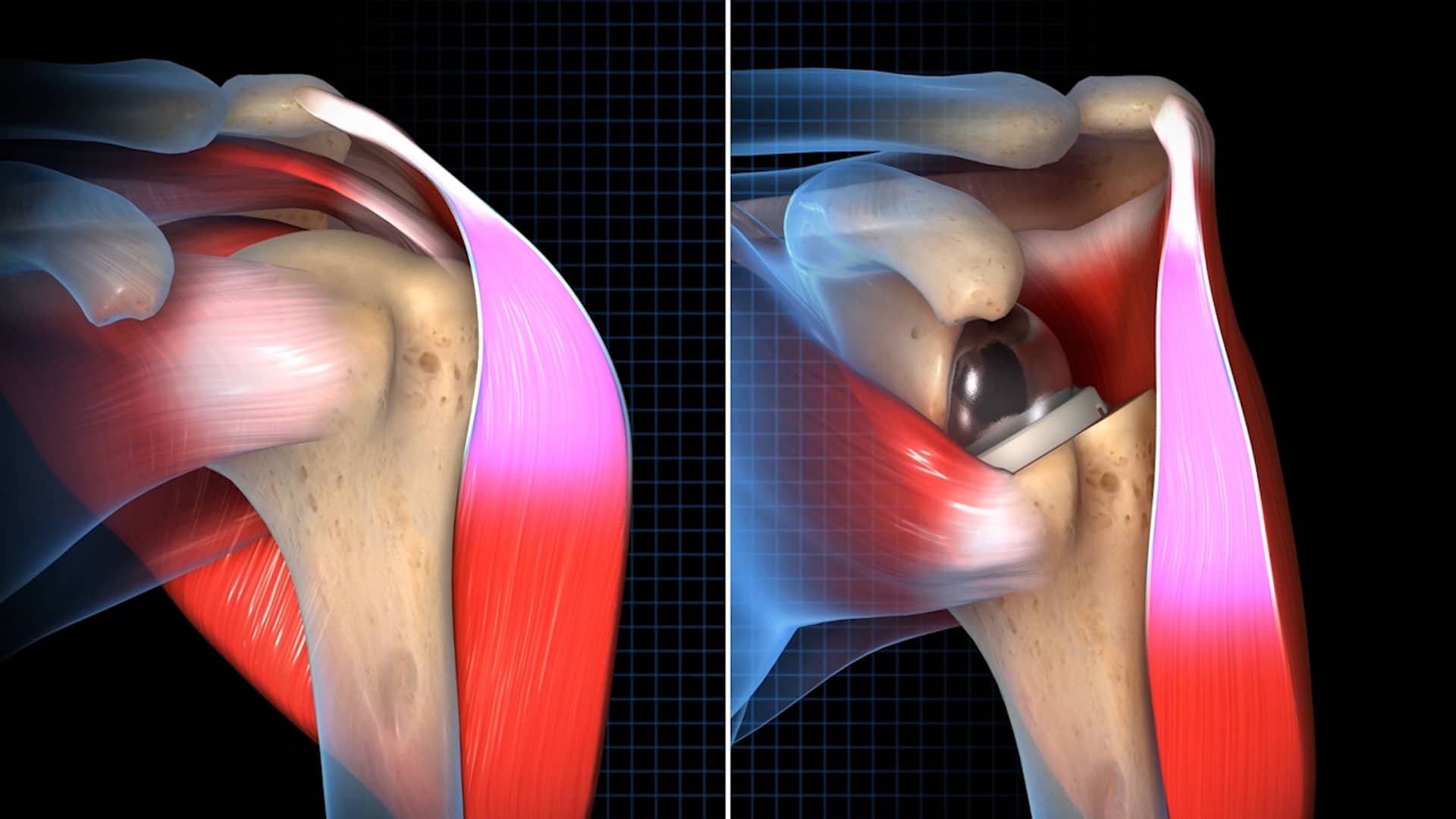

These shoulder implant variations apply to either a typical or reverse setup. The typical replacement uses an artificial joint resembling the anatomy of a human joint, while the reverse setup is opposite to the natural placement of the ball joint. For shoulder replacement surgery the implant used depends on the condition of the rotator cuff. A torn or damaged rotator cuff means the surgeon chooses the reverse alternative.

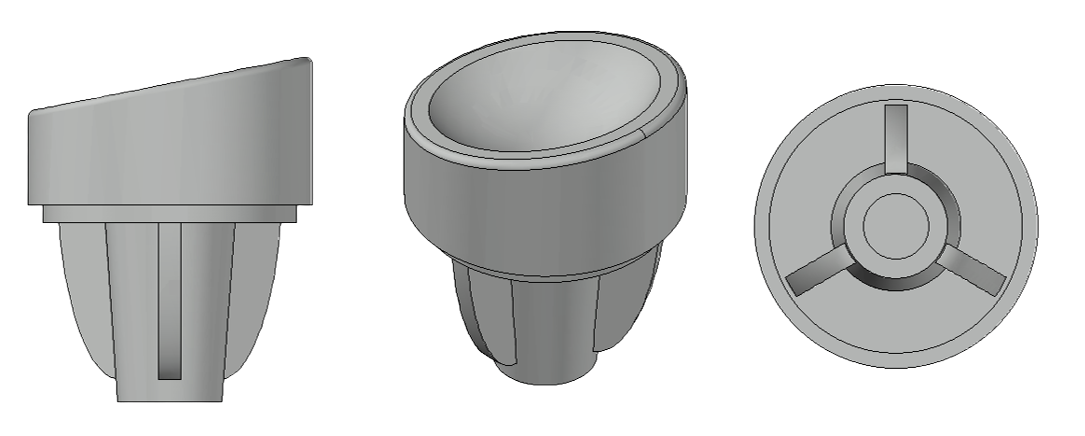

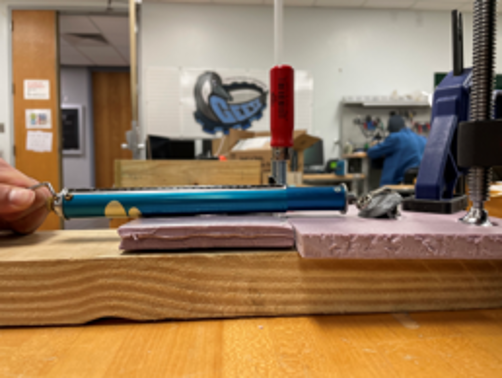

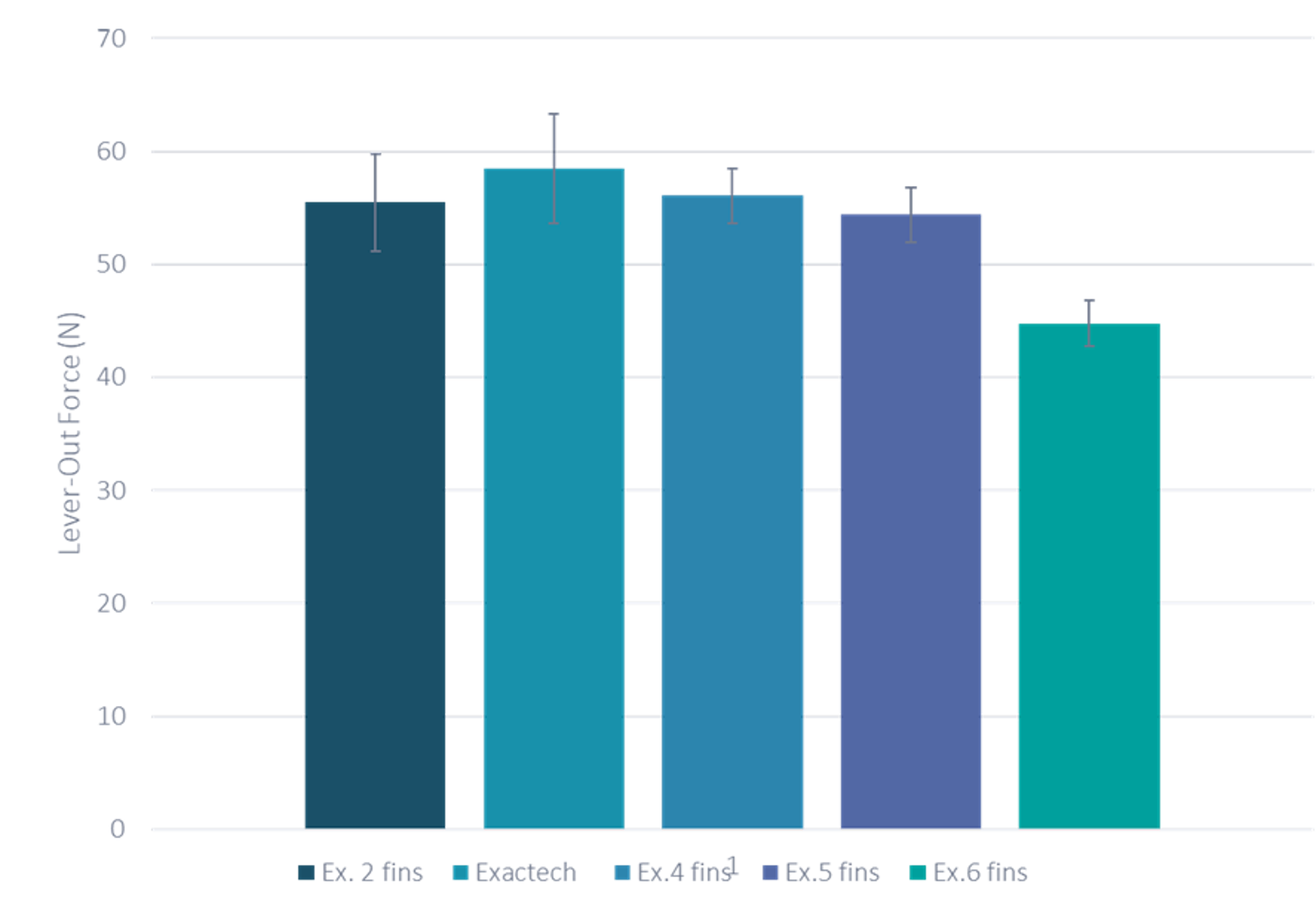

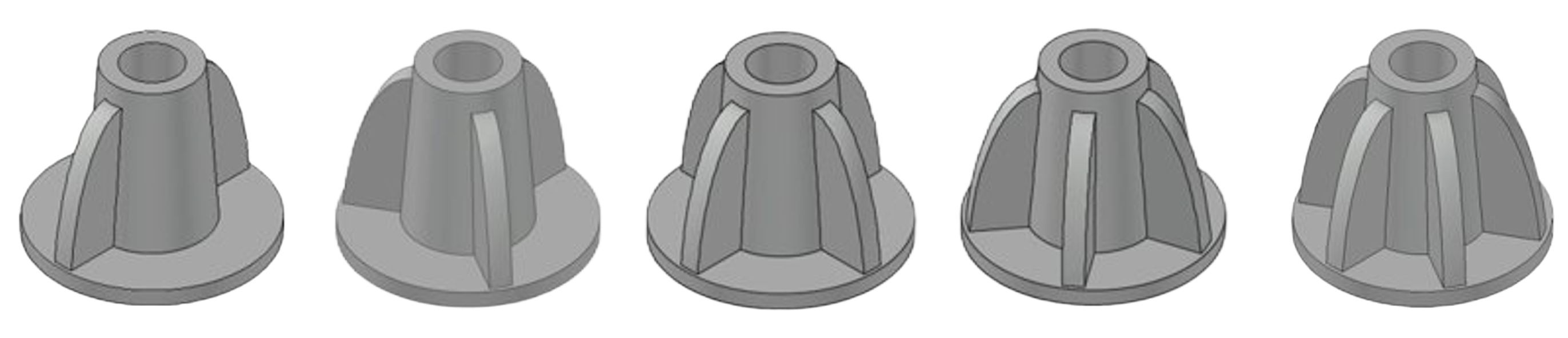

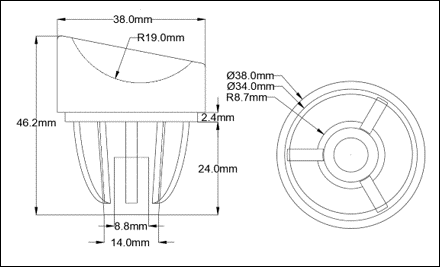

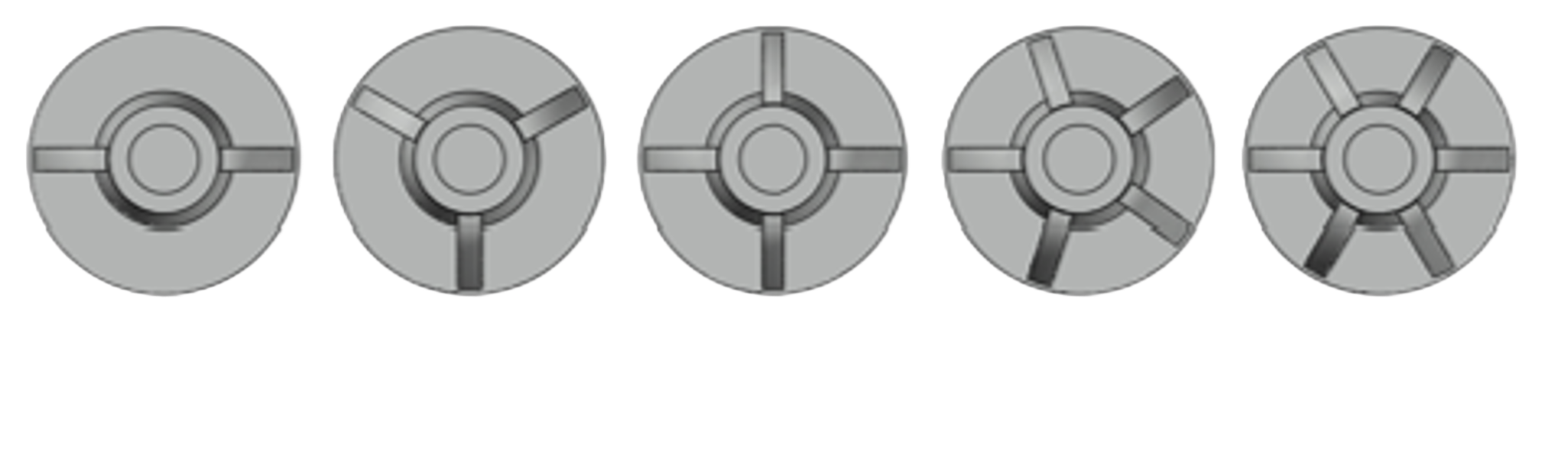

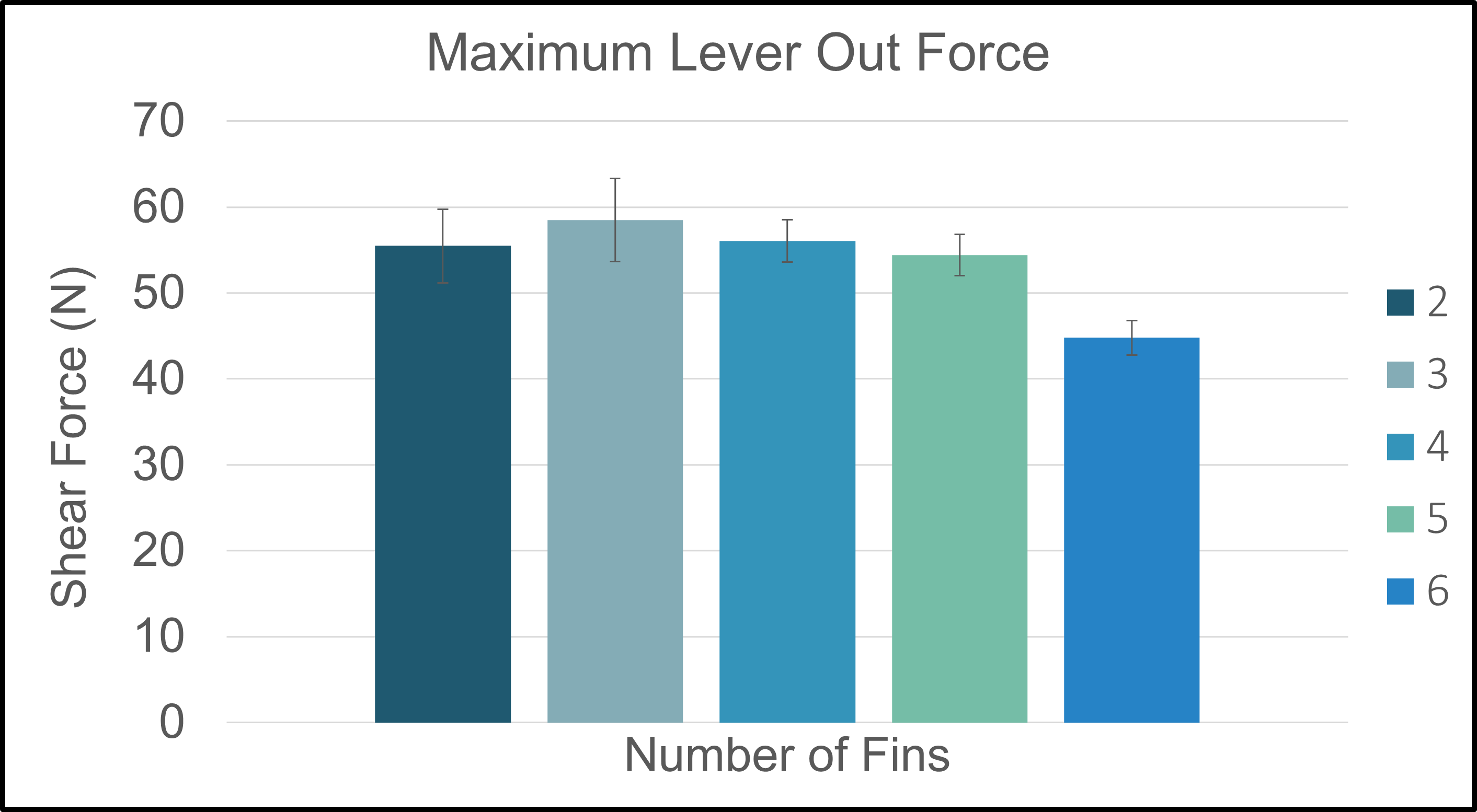

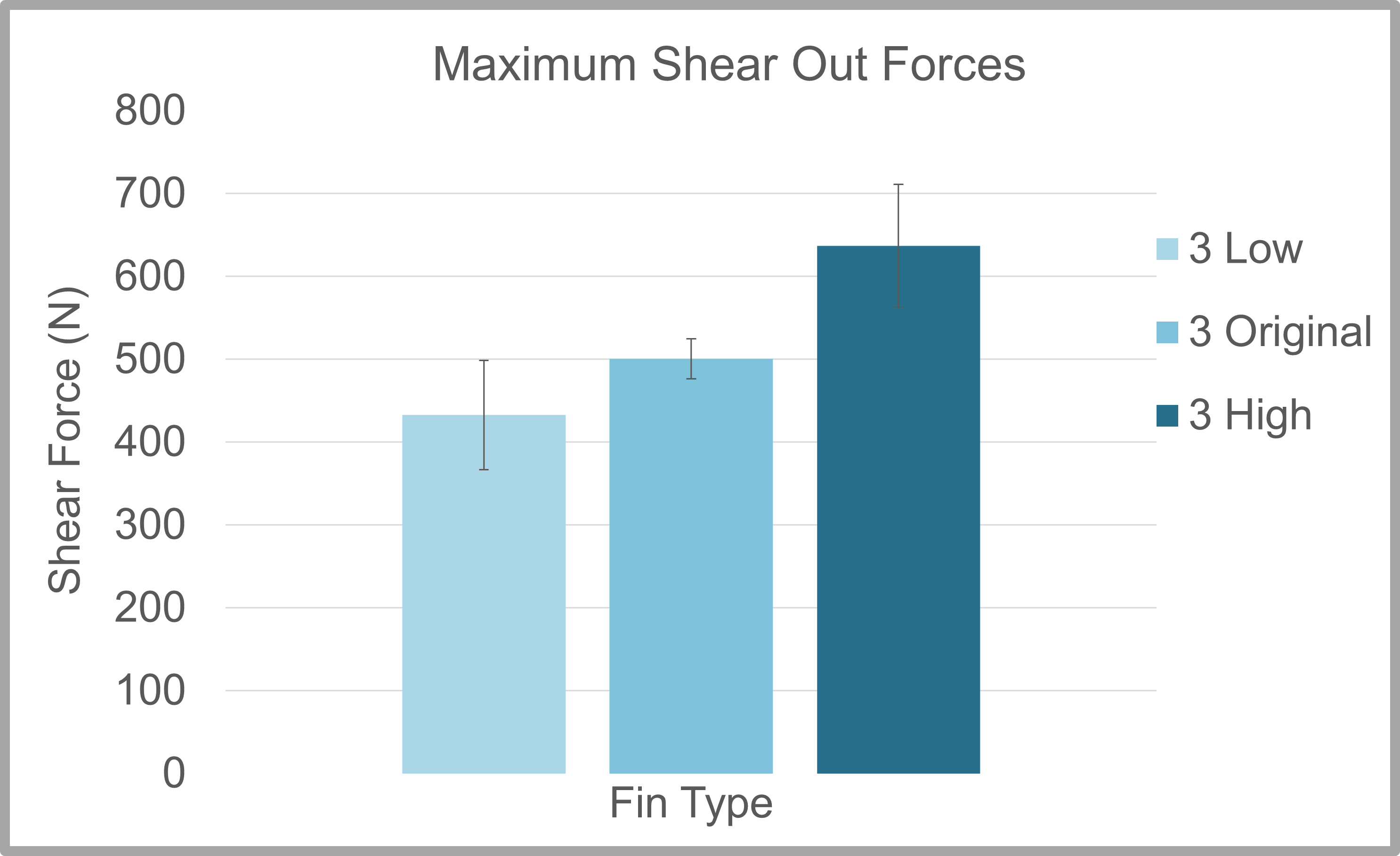

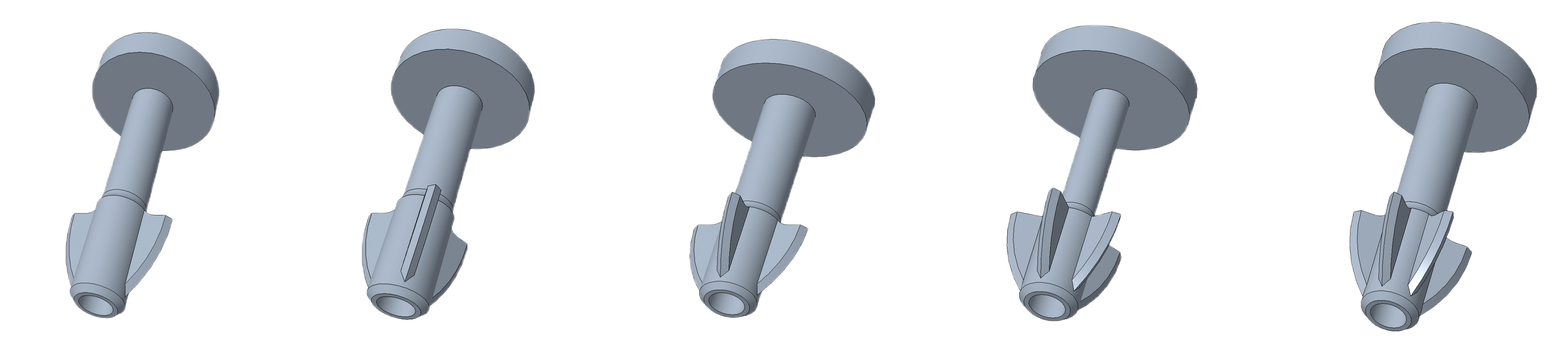

When a reverse shoulder implant loosens from its joint, it is from a lack of static friction. This results in a biomechanical moment to occur. Our team redesigned the implant around this idea. Through a series of tests applying directional forces to the implants, we determined which design was most effective in reaching Exactech’s goal. We eventually built our own testing mechanism to decide which redesign best fulfilled our role in replacing Exactech’s design.

Once we picked our design, we made further changes to make the implant more suited for surgical revisions. This included spacing and removing fin area. Our resulting reverse stemless design increased the longevity of Exactech’s implant by decreasing the rate it will loosen from the joint.

The Cold Shoulderz

Analysis Engineer

Design Engineer

Design Engineer

Design Engineer

Analysis Engineer

Design Engineer

Depending on the results from testing we will add further improvements to the design. These improvements include material changes; more variations in testing; gathering of additional data; and surface coating changes.